How to Choose the Right Hydraulic Torque Wrench for Your Application

10 June 2025

Selecting the correct hydraulic torque wrench is essential for ensuring accurate and safe bolting operations.

Whether you're working in construction, manufacturing, oil & gas, mining or maintenance, using the wrong tool can result in over- or under-tightening, leading to equipment failure, costly downtime, or safety risks. This article outlines how hydraulic torque wrenches work, the types available, and the key factors to consider when choosing the best tool for your specific application.

Understanding Hydraulic Torque Wrenches

Hydraulic torque wrenches are precision tools used to apply a specific torque to fasteners such as bolts and nuts. They are most commonly used in heavy-duty industrial applications where manual tools are either inefficient or not capable of delivering the required torque.

A typical hydraulic torque wrench system includes the following components:

- Drive Unit: This is the main body of the torque wrench and houses the hydraulic cylinder that powers the tool. When pressurised hydraulic fluid enters the cylinder, it moves a piston, which in turn drives the ratchet mechanism or rotating drive.

- Output Head: This could be a square drive that allows attachment of standard impact sockets or a low-profile hexagon cassette, depending on the application.

- Hydraulic Pump and Hoses: The pump provides pressurised hydraulic fluid to the drive unit via high-pressure hoses. Pumps may be manually operated, electric, or air-powered, depending on the site conditions and application needs.

Types of Hydraulic Torque Wrenches

Hydraulic torque wrenches are generally classified by their design and application suitability:

Square Drive Hydraulic Torque Wrench

- Features a square drive mechanism that accommodates a variety of impact sockets

- Ideal for general-purpose bolting tasks

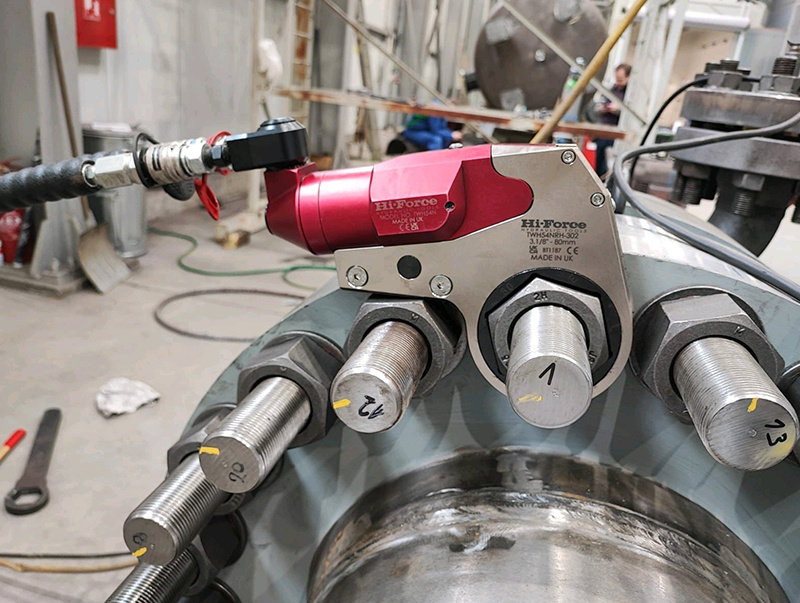

Low-Profile Hexagon Hydraulic Torque Wrench

- Designed for applications with low overhead clearance or limited side space

- Utilises slimline, interchangeable hexagon ratchet cassettes

Key Considerations When Selecting a Torque Wrench

To ensure optimum performance, safety, and longevity of your equipment, consider the following factors when selecting a hydraulic torque wrench for the job.

1.Accessibility – One of the first aspects to consider is how much physical space is available around the bolted joint. In confined or difficult-to-access areas, low-profile hydraulic torque wrenches like the Hi-Force TWH-N Series are ideal. These tools are specifically designed to fit into tight or recessed spaces, thanks to their narrow cassette heads and compact structure.

For more open spaces and general bolting applications, square drive models like the Hi-Force TWS-N Series are an ideal option.

2. Torque Output Requirements – Another crucial factor is the required torque range for your application. It’s important to identify both the minimum and maximum torque values needed for your operations. This ensures the tool you choose is capable of delivering the required force without being over- or under-utilised, which could affect performance and tool lifespan.

Hydraulic torque wrenches from Hi-Force offer standard torque capacities of up to 48,181 Nm (34,985 lbf.ft), making them suitable for a wide range of industrial needs.

3. Working Environment – The conditions in which the tool will be used also play a vital role in tool selection. Factors like extreme temperatures, humidity, exposure to chemicals, or the presence of flammable gases must all be considered.

In hazardous environments where the risk of ignition is present, use air-driven torque pumps to reduce the risk of explosion. In standard industrial environments, electric torque pumps are often preferred for their precise pressure control and consistent performance.

4. Cassette and Socket Compatibility – To ensure reliable and repeatable torque application, the output head of the tool must be properly matched to the bolt size and type.

Hex Cassette Selection: For low-profile torque wrenches, ensure the cassette matches the Across Flats (AF) size of the bolts.

Impact Sockets: With square drive wrenches, select the appropriate impact socket size based on bolt dimensions.

5. Accessories – Depending on the application, you may need to adapt or enhance the tool for better control and accessibility by using suitable accessories. These include extended reaction arms, hexagon reducer bushes, square drive conversion kits, removable handle kits, backup wrenches, etc.

These accessories not only extend the functional range of the tool but also contribute to improved operator ergonomics and safer working practices.

Summary

Hydraulic torque wrenches are essential for delivering controlled, repeatable, and safe torque in demanding industrial environments. With multiple types and configurations available, selecting the right tool requires careful consideration of the application's specific requirements, including space constraints, torque range, and working environment.

At HES, we provide a wide range of options from Hi-Force, a leading British manufacturer of hydraulic tools known for quality and reliability. The range covers everything from compact low-profile cassettes ideal for confined spaces to high-capacity square drive models suited for general industrial use. Each product is built on years of engineering expertise and stringent design standards, ensuring optimal performance even in the most demanding bolting tasks.

If you're unsure about which hydraulic torque wrench best suits your needs, our team of experts is here to help. We can guide you through the selection process, recommend the most suitable equipment, and provide technical support or training where needed.

Browse the full range of Hi-Force hydraulic torque wrenches or get in touch with your local HES Sales Engineer to discuss your requirements.

Related articles

Hi-Force Strengthens Heavy Lifting Portfolio with the New HCJ Climbing Jacks

Hi-Force HCJ climbing jacks - compact, lightweight, and built for precision heavy lifting even in tight spaces...

Read more

HES Expands Industrial Tooling Range Through Partnership with RenQuip

We're delighted to announce a new partnership with RenQuip, a British manufacturer of high-quality flange working equipment...

Read more

EBT-CA Series: Discover the Next Generation of Smart Torque Tools from Norbar

The latest evolution in Norbar’s range, EBT-CA is setting new standards for precision and connectivity in the torque multiplier market...

...Read more