Torque vs Tension

3 November 2020

Customers are often unclear as to whether or not torque or tension, is the most suitable approach to their specific application.

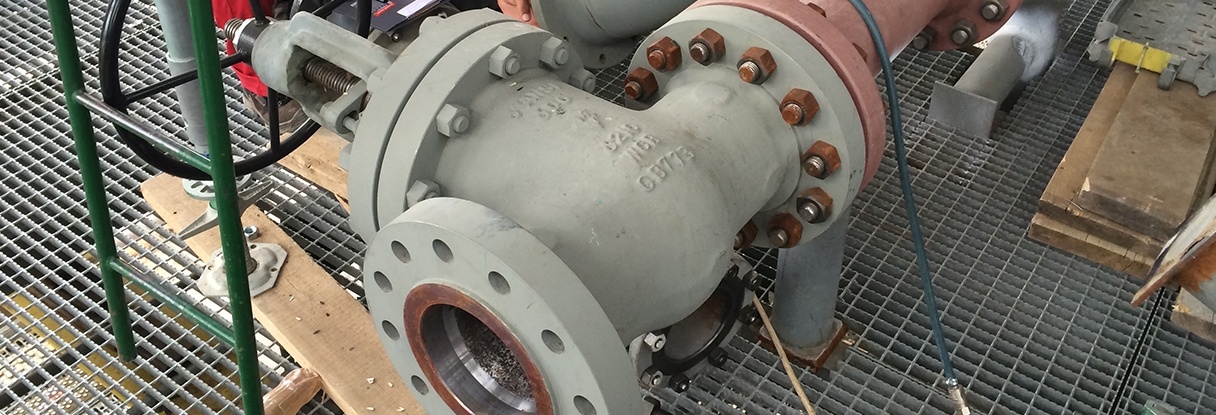

The process of tightening and achieving the correct residual bolt load to maintain acceptable integrity can be achieved through both techniques however the two methods are very different, and various factors need to be considered before making the most suitable selection.

The relationship between tension and torque should be looked at cautiously, since it is very difficult to indicate the range of conditions expected to be experienced by a fastener.

Bolts are designed to stretch just a small amount, and this elongation is what clamps the joint together. The elasticity of the material used in the bolt’s manufacture causes it to want to return to its original un-stretched shape. This inherent bolt spring tension causes the clamping force and together with the friction in the bolt’s threads, work to prevent loosening. So, ensuring proper clamping force and the maintenance of that clamping force is a function of ensuring that enough spring tension is created in the bolt while tightening it. Both torque wrenches and bolt tensioners work to create this spring tension by stretching the bolt. However, they use different means to accomplish it.

“Torque” is simply a measurement of the twisting force required to spin the nut up along the threads of a bolt, whereas “Tension” is the stretch or elongation of a bolt that provides the clamping force of a joint.

Torque is a very indirect indication of tension, as many factors can affect this relationship, such as surface texture, rust, oil, debris, thread series and material type just to name a few.

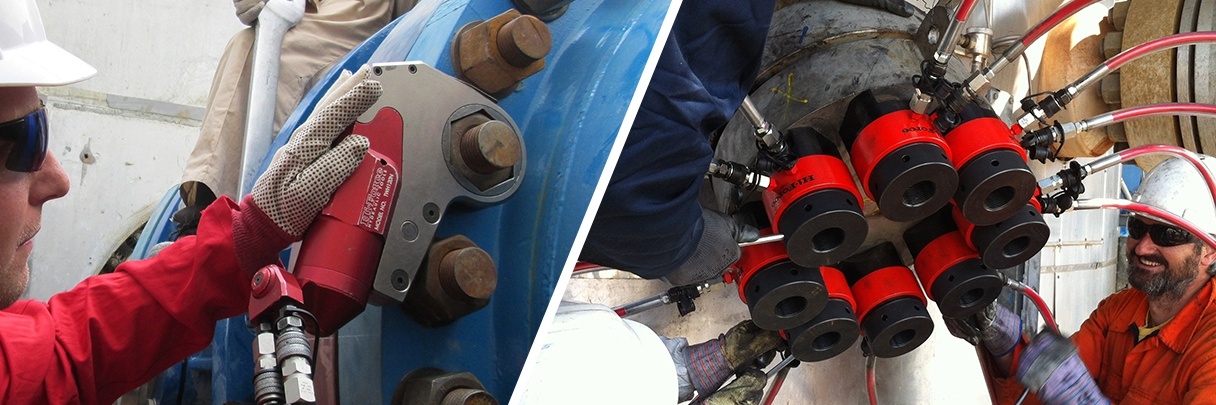

Torque wrenches provide this tension by the amount of rotational force they apply to the bolt. As the force is applied, the threading draws the nut face and bolt head closer together, stretching the bolt and creating the clamping force. This is the most common form of providing load to a bolt. The factors to be considered before using a hydraulic torque wrench to provide this for are;

- The finish used on the bolts

- Whether or not flat washers are used

- The number of times that the bolt has been used

- Cleanliness of the bolt

- Whether or not a lubricant has been applied to the threads and nut face

Bolt tensioning works by preloading the bolt, stretching it before the nut is tightened. The tensioner is clamped to the bolt’s threads and pushes against the flange in the surface being bolted. This provides a very consistent amount of stretch to the bolt, ensuring consistent bolt stretch and clamping force.

The drawback to bolt tensioners is that they must be selected specific to each application. Much more data must be compiled and considered in the selection of a tensioner such as:

- Bolt diameter

- Free stud protrusion length

- Nut size

- Washer thickness and diameter

- Bolt grade

- Bolt load requirement

So, which method is most suitable?

Decisions have to be made about torque vs. tension based on both performance requirements and budget. If you base your decision on torque vs. tension strictly on budget, irrespective of performance, any problem flange/application encountered can escalate your budget out of the proportion trying to repair these issues.

It is necessary to understand your needs. If your applications have a lot of bolts to tighten, torque with a high quality torque wrench is a good option. However, if you have a “Critical Path Application” and you require accurate results and even bolt load, tension is worth any potential additional cost.

Both ranges of tools have their advantages and their disadvantages and it is important to use the method recommended by the manufacturer.

Related articles

Hi-Force Strengthens Heavy Lifting Portfolio with the New HCJ Climbing Jacks

Hi-Force HCJ climbing jacks - compact, lightweight, and built for precision heavy lifting even in tight spaces...

Read more

HES Expands Industrial Tooling Range Through Partnership with RenQuip

We're delighted to announce a new partnership with RenQuip, a British manufacturer of high-quality flange working equipment...

Read more

EBT-CA Series: Discover the Next Generation of Smart Torque Tools from Norbar

The latest evolution in Norbar’s range, EBT-CA is setting new standards for precision and connectivity in the torque multiplier market...

...Read more